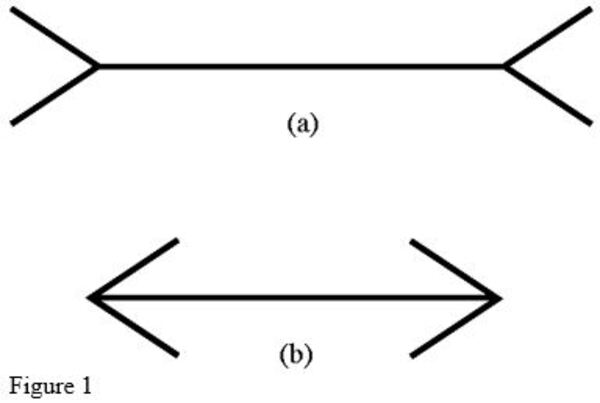

We often receive questions from splicers observing gainers and abnormally high splice losses that they cannot correct, even after re-splicing several times. This should sound familiar. It is the typical observed result when splicing G.652.D glass to G.657 bend insensitive glass, but like the example in Figure 1, it is an illusion.

Historically, the standard glass placed in outside plant (OSP) fiber optic cables was G.652.D glass. The industry, however, started shifting to G.657 bend insensitive glass as a standard OSP offering within the last five years. Splicing these different glass types together will yield excellent and acceptable splice losses; however, an OTDR displaying a splice from one direction or the other will often show odd and inaccurate results.

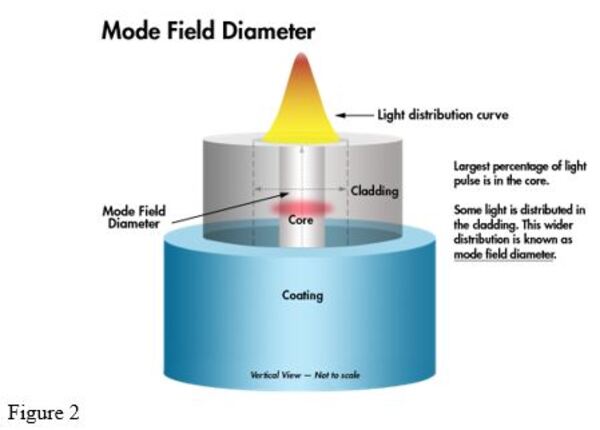

What is the difference between the two glass types that causes this effect? It is the mode field diameter (MFD). MFD is defined as the area in the optical glass where the mode of light travels. While most of the light energy will travel in the core of the glass, some of the light spills over into the cladding as it travels. That combined area is called the MFD (Figure 2).

A smaller MFD is needed to create a glass that is bend insensitive as it provides a more focused area for the light to make it through tighter bends than standard single mode glass.

CLICK TO TWEET: In this blog CommScope's Chris Gemme explains high splice loss, the effects of Mode Field Diameter.

What do standards say about MFD? Telecordia GR-20 references IEC 60793-2-50. It allows a median MFD range of 8.8 to 9.3 microns in single-mode optical fibers. Splicing two fibers with mode field diameters that are not the same will lead to the measurement challenges we described above, even if both fibers are within the allowable range.

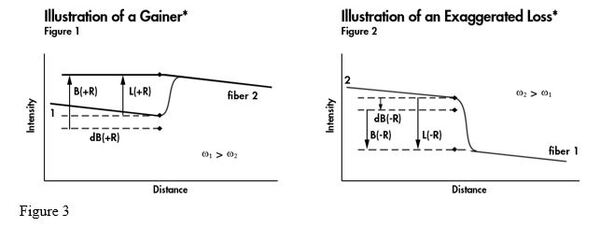

Why does OTDR present an inaccurate high splice loss or even a “gainer” in this situation? MFD effects the backscatter of the source pulse, which is what the OTDR is using to calculate an estimated splice loss. Changes in MFD will cause the backscatter to appear as either an exaggerated loss or gainer to the OTDR receiver, depending on the direction the source pulse is travelling through the splice.

Variances in MFD are normal under all circumstances, but there are occasions where two fibers have MFD far enough apart that they present themselves in this fashion, such as G.657 and G.652 glass.

Figure 3 shows how a splice with actual loss dB (+R) will display on and OTDR when observed as two unidirectional scans. That’s why the use of unidirectional OTDR testing may occasionally result in inaccurate loss measurement of a fiber splice. To make an accurate measurement of splice loss, this effect must be corrected through bidirectional averaging.

ANSI/TIA/EIA-455-8-2000 as an industry specification states the splice loss measurements with an OTDR must be conducted from both directions and averaged (by adding with signs) for accurate splice loss.

The use of unidirectional OTDR measurements for measuring system performance is problematic in that it presents only an estimated splice loss, impacted by the effects of backscatter variances caused by varying mode field diameters. The greater the difference in MFD, the greater the variance in backscatter, resulting in exaggerated and inaccurate unidirectional splice loss values. To correct the OTDRs inaccuracy because of this effect, it is important to use a bidirectional average which provides an actual splice loss measurement.

How often do you need to correct OTDR inaccuracies in your network?